Stable. Robust. Calm run.

Gruber Straw Mill - Straw Ripper

Processing of:

Straw bales, round bales and loose straw, hay, taxis, tree bark, reeds, maize stalks and other media can be processed.

Intended use of the ground material:

Bedding, fodder, fuel. The ground straw is also used as ballast feed in ruminant feeding. As a raw fibre supplement, digested straw is well absorbed by most animals.

The cutting length of the straw can be varied between 10 and 50 mm, depending on the sieve used.

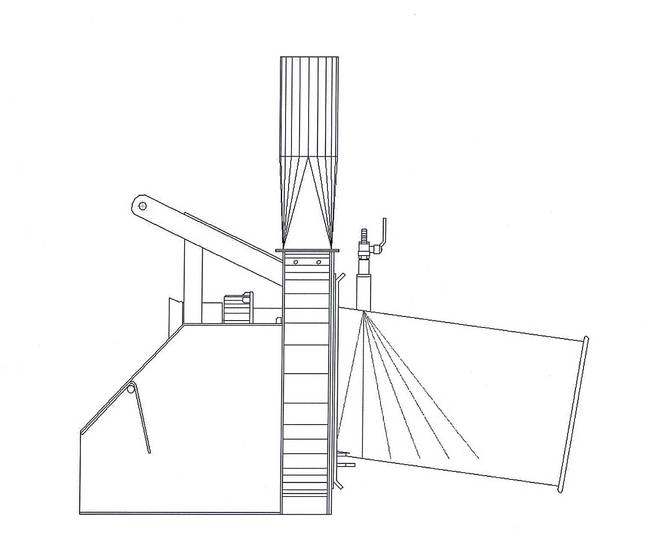

Dust-reduced straw processing with Gruber straw shredder:

By installing a nozzle block in the straw suction bonnet and thus spraying the straw very finely with water from the water pipe, the dust is effectively bound to a large extent. The straw processed in this way does not get wet. Many practical tests confirm the effectiveness of this dust binding. It is possible to retrofit the nozzle block to Gruber straw shredders already in use.

What are the particular advantages of digested straw?

The Gruber Straw Ripper will shred any straw. The surface of the stalk is broken open and the inside is exposed. As a result, the stalk processed in this way can absorb considerably more liquid due to its enlarged surface. This straw bedding can be used sparingly as it has 6-10 times greater absorbency than normal straw.

- Storage space capacity can be kept much smaller, as digested straw stores much more densely.

- With liquid manure, congestion in the channels is avoided because such straw mixes better with the manure.

- Broken down straw improves the fertilising effect of the slurry or manure.

- The decomposition to humus is much faster because the structure of the straws is already crushed.

- The thermal insulation effect is excellent and surpasses normal straw by far.

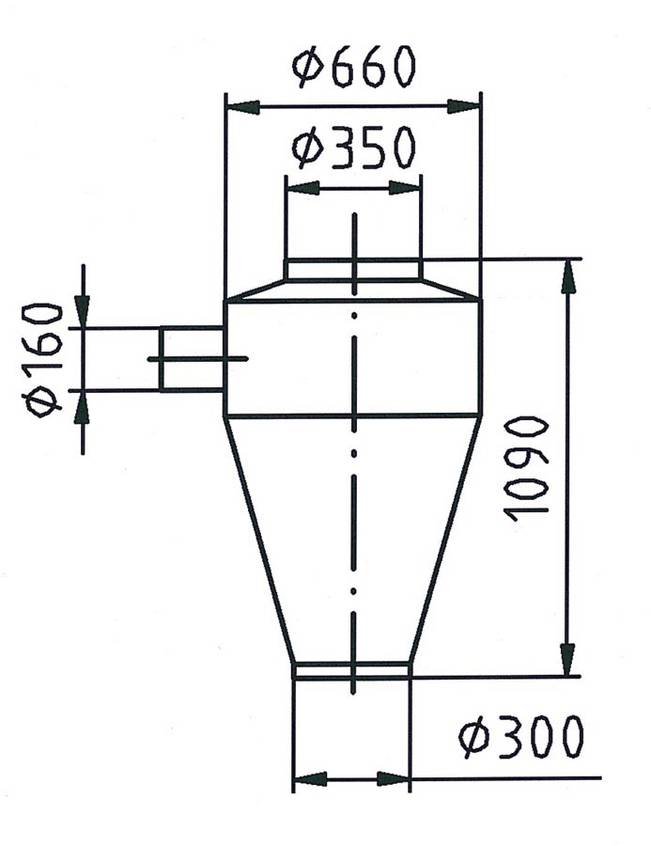

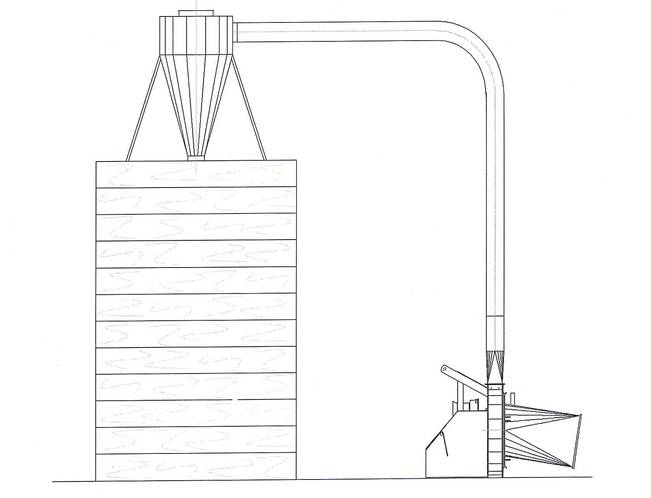

Processed material can be blown directly into the barn, wooden silos or storage rooms. Air outlet must be provided. A cyclone is recommended for processing without special rooms.

| Type | SZ 2000 | SZ 2000 | SZ 2000 | SZ 3000 | SZ 4000 |

| Drive | Electric motor | Electric motor | Tug | Tug | Tug |

| KW | 15 kW | 18.5 kW | 25-70 kW | 50-120 kW | 110-250 kW |

| approx. output /h depending on drive force and fineness | 500-1200 kg/h | 600-1500 kg/h | 1000-2000 kg/h | 1500-3000 kg/h | 2000-5000 kg/h |