Gruber grain handling

Conveyor technology

The KS series grain augers from Gruber convey all types of grain, beans, peas and other free-flowing goods. The worm motor is mounted with the V-belt drive above the outlet.

For the grain intake at the bottom of the inlet, there are different inlet protection baskets depending on accessibility or danger areas.

There are various accessories for the grain snails: Such as, for example. Trolleys, flexible discharge pipes, etc.

The grain augers from Gruber Getreidetechnik are available in the following versions:

- Grain auger KS 100 Ø, 1.5 to 12.5m length

- Grain auger KS 120 Ø, 1.5 to 12.5m length

- Grain auger KS 150 Ø, 1.5 to 12.5m length

- Grain auger KS 200 Ø, 3.0 to 9.0m length

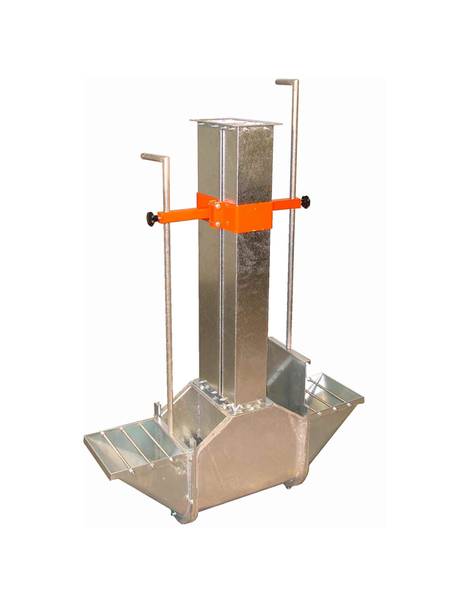

The Gruber KK Series Grain Conveyor Cannon handles all types of grain, beans, peas and other free-flowing commodities. The worm motor is mounted with the V-belt drive under the intake gate. This results in a low centre of gravity, which makes the grain gun easier to handle.

The feed gate of the feed gun enables exact metering of the feed quantity. 2 transport wheels are fitted as standard for moving.

There are various accessories for the grain snails: Such as, for example. Trolleys, flexible discharge pipes, etc.

The grain guns KK from Gruber Getreidetechnik are available in the following versions:

- Grain Cannon KK 100 Ø, 1.5 to 12.5m length

- Grain Cannon KK 120 Ø, 1.5 to 12.5m length

- Grain Cannon KK 150 Ø, 1.5 to 12.5m length

- Grain Cannon KK 200 Ø, 4.0 to 12.0m length

The Gruber HS auger conveyor is a connecting auger conveyor with pipe connection at the inlet and outlet. For this reason, this auger conveyor is used in grain plants for short distance or height bridging.

The reinforced design of the inner auger enables commercial use.

The following types are available:

- Lifting auger HS 150 Ø, 2.5m to 4.5m length

- Lifting auger HS 200 Ø, 3m to 6m length

- If desired, the inlet can be at the top of the motor at 45° or 90°.

The Gruber Gigant Type KG grain cannon with undercarriage can be pulled and is equipped with a drawbar as standard.

The folding joint makes the delivery gun easy to shorten for transport and thus easy to transport with the tractor.

The following types of Gruber grain cannon type KG are available:

- Gruber grain cannon Gigant KG 150 ∅ (output: approx. 15 – 25 t/h)

- Gruber grain cannon Gigant KG 200 ∅ (output: approx. 25 – 40 t/h)

The Gruber trough auger is used for horizontal conveying of grain and other granular materials – e.g. above or below a row of silos. In order to be able to adapt to a variety of different uses, the augers can be angled on and off. The permissible adjustment angle is approx. +/- 20 degrees. Angling the Gruber trough auger leads to a reduced hourly output.

The following types of Gruber trough auger are available:

- Gruber trough auger TS 150N, max. 18 t/h

- Gruber trough auger TS 150H, max. 21 t/h

- Gruber trough auger TS 200H, max. 30 t/h

- Gruber trough auger TS 250H, max. 45 t/h

The Gruber chain elevator is suitable for vertical transport of all types of grain, maize, beans, peas, dry and wet maize and other free-flowing goods.

The chain elevator is used for small to medium conveying capacities of 15 to 40 t/h.

The Gruber chain elevator can not only transport vertically but also at an angle, for example along a sloping roof. This can save subsequent conveyor equipment (lengths).

The Gruber chain elevator differs from other manufacturers by its extremely stable construction of elevator foot, elevator head and driver chain.

The gutter auger or side auger for Gruber elevators is used to feed grain in the receiving gutter to the chain or bucket elevator.

There are 3 variations:

- The mould auger can be driven directly by the KE 20, KE 30 and KE 40 chain elevator.

- From a length of approx. 6 m, the gutter auger is driven separately from the elevator as a side auger with a gear motor.

- For feeding bucket or chain elevators, the mould auger can be driven with a V-belt drive (up to 15m length possible).

Gratings are made of primed frame in bolted version. The bars are made of shaped tube and are galvanised with 40 x 80 x 3.

The bars are available in the following lengths:

- 1,2m – max. Wheel load 3,0 to

- 1,5m – max. Wheel load 2,5 to

- 2,0m – max. Wheel load 1,5 to

The Gruber bucket elevator is used for medium to high conveying capacities and for high running times per day or in continuous operation.

Gruber bucket elevators are an economical and operationally reliable solution for vertical conveying of larger quantities of grain as well as seeds, horse beans, ground goods and granules.

Gruber bucket elevators are characterised by high quality and reliability.

The following types are available:

- Gruber bucket elevator BE 30, approx. 30 t/h

- Gruber bucket elevator BE 40, approx. 40 t/h

- Gruber bucket elevator BE 60, approx. 60 t/h

- Industrial bucket elevators with a capacity of up to 200 t/h.

The Gruber intake chute conveyor is a trough chain conveyor which is used to take the grain from the trailer or truck in the tipping chute. The mode of operation is the same as for the trough chain conveyor, but it has a conveyor shaft that is open at the top and connected to the (concrete) gutter slope.

The following types of Gruber Gutter Conveyor are available:

- Gruber Gutter Conveyor AG 30, approx. 30 t/h

- Gruber Gutter Conveyor AG 40, approx. 40 t/h

- Gruber Gutter Conveyor AG 60, approx. 60 t/h

- Gruber Industrial Casting Conveyor up to 200 t/h

Gruber trough chain conveyors are conveying systems (mechanical continuous conveyors with traction) suitable for grain and bulk material transport in which an endless chain with carriers (crossbars) runs in a closed trough. Depending on the system situation, horizontal or slightly ascending conveying is possible. Gruber trough chain conveyors, also known as Redler, are used for medium to higher conveying capacities and running times.

The following types are available:

- Gruber TF 30 trough chain conveyor, approx. 30 t/h

- Gruber TF 40 trough chain conveyor, approx. 40 t/h

- Gruber TF 60 trough chain conveyor, approx. 60 t/h

- Gruber Industrial Trough Chain Conveyor up to 200 t/h

Do you have winding grain storage areas or long conveying routes? Here, the conveying fan or suction-pressure blower is the optimal conveying system.

The pressure fan with rotary valve and inlet funnel is designed for delivery rates of 6 to 16 t/h depending on the motor power and can be converted to a suction fan on request.

The suction-pressure fan is equipped with a rotary valve, suction cyclone and 3.2m suction nozzle and has an output of between 6 and 13 t/h, depending on the motor.

Flexible spiral conveyors from Gruber are ideal for conveying grist, grain, pellets or floury goods.

Flexible auger conveyors from Gruber are subject to little wear and tear because the conveying spirals are made of high-quality steel and the outer tube is made of plastic specially manufactured for this purpose.

The following types are available:

- Conveyor spiral FS 75 Ø75mm – capacity approx. 800 – 1200 kg/h

- Conveyor spiral FS 90 Ø90mm – capacity approx. 1500 – 2500 kg/h

- Conveyor spiral FS 108 Ø108mm – capacity approx. 3500- 7000 kg/h